ENGINE TURNING STAINLESS STEEL vs BRUSHED STAINLESS STEEL

IVE OUTDOOR

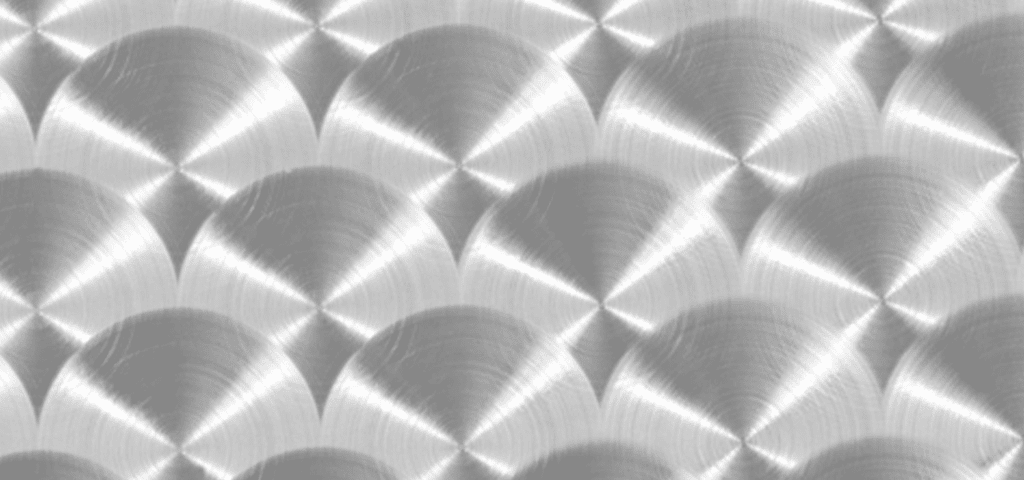

Engine Turning Stainless Steel

What is Engine Turning Stainless Steel?

Engine Turning Stainless Steel is a technique for the decorative processing of stainless steel, which consists in creating a repeating, geometric pattern in the shape of a circle. It is a time-consuming and laborious process, but the end result is highly appreciated for its beauty and durability.

Engine Turning Stainless Steel is recommended for unpainted equipment. This finish, combined with the longevity of the devices, allows you to keep the beautiful appearance of the devices for many years. The Engine Turning structure makes even mechanical damage caused during long-term use invisible.

Brushed Stainless Steel

What is Brushed Stainless Steel?

Brushed Stainless Steel is a type of stainless steel finish that features a matte surface and a uni-directional sanding pattern across the entire surface of the metal. This type of surface finish is known for its durability and easy maintenance – it is used in products where a clean and modern look is desired.

Brushed Stainless Steel is recommended as an addition to painted equipment. Each device is painted in about 75% of the surface, so about 25% of the elements remain unpainted and such elements with a Brushed Stainless Steel finish blend perfectly with the painted elements of the device. The Brushed Stainless Steel finish allows you to easily eliminate any possible scratch caused by mechanical damage – in this case, just wipe the steel with any abrasive stock.